- Improving inventory tracking

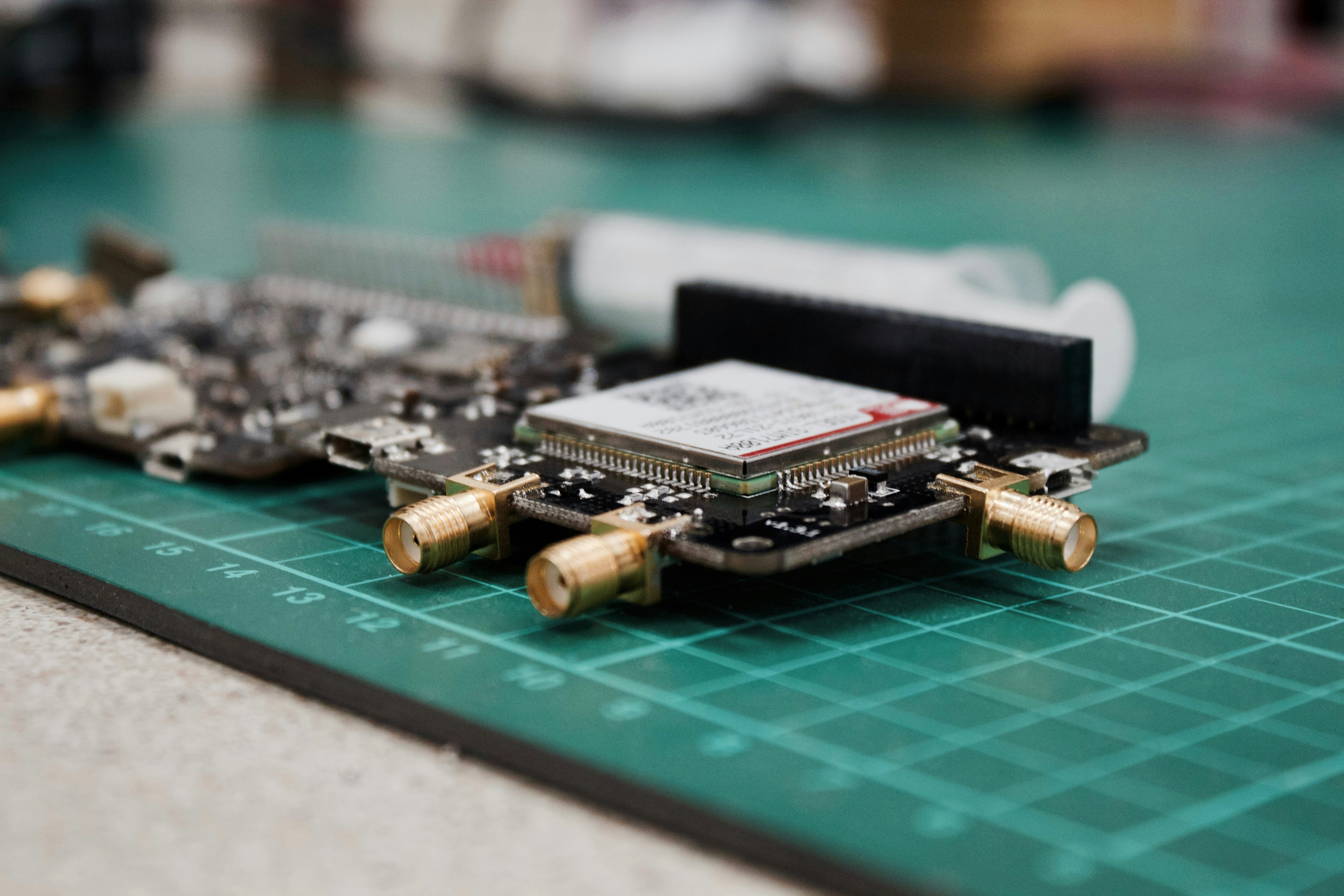

Manufacturers take advantage of IoT devices to track their inventory in any part of the world and in real-time. With Radio Frequency Identification (RFID) tags, manufacturers will receive real-time information about their products from wherever they are. This helps them manage their inventory and optimize them for improved efficiency. With real-time information, they can give their customers the correct arrival dates for their shipments or notify them of delays where necessary. This technology also allows them to trace finished products and any product recalls.

- Enhancing supply chain transparency

As seen above, companies can see where their products are at any given time, thanks to IoT technology. With the correct implementation of this technology, customers are able to track their product from source to destination and in every part of the production chain. Because of this, transparency in the supply chain is enhanced, and customers can understand where their product is at any given time. With enhanced visibility, supply chain interruption is minimized, and customers’ trust is earned because any issue is identified and communicated clearly for better efficiency.

- Predictive maintenance

This is perhaps one of the most significant advantages of IoT. With this, IoT sensors help identify when machines need maintenance based on different aspects such as heat, vibration, and humidity, among other data points. Armed with the correct data from sensors fitted into a machine, machines are repaired on schedule before they completely come to a halt or break up completely. Instead of waiting for them to fail during production, which is the worst thing that can happen, different types of equipment are fixed when their problems are minimal. This saves on time that could have been lost and minimizes the cost of maintenance.

- Tracking temperature on cold chain transport

Monitoring cold chain transport is one of the complex tasks in supply chain management that requires accuracy. This is mainly the case when it comes to tracking temperatures of products being transported that mainly fall in the category of food items perishables and eatables to ensure they remain fresh and their quality is intact. With IoT sensors, this can be achieved using predictive and descriptive analysis, that monitors them and sends data in real-time. In case the temperature rises above the required levels, an alert is sent in real-time, along with the location of the items.

- For improved fleet management

IoT can be used to manage fleets' operations and environment. Through the connection of the fleet to IoT, companies can ensure their transport remains on the road longer. This technology also allows supply chain and logistics firms to get the real-time tracking of their fleet at a lower cost and enhance efficiency. This improves the last-mile delivery of products, leading to repeat orders from consumers. With the information provided by the sensors, companies can streamline their operations and increase customer retention.